Hapstone Premium CBN is a new series of CBN stones for sharpening knives using guided knife sharpeners (Hapstone, TSPROF, and other Edge Pro-compatible sharpening systems). Hapstone Premium CBN utilizes advanced hybrid metal-polymer binder - composite of traditional copper-tin alloy and polymer components. Hybrid binder inherits exceptional wear resistance and cutting performance of metallic binder.

Narrow stones (12mm wide) are suitable for recurved blades.

CBN (Cubic Boron Nitride) is the second-hardest material after diamond. Hapstone Premium CBN consists of a 3mm thick CBN-bearing layer mounted on a premium black aluminum blank.

CBN's qualities include high levels of high hardness, strength, abrasion resistance, and thermal and chemical resistance. These characteristics exceed the values of synthetic diamonds and conventional abrasives such as silicon carbide and aluminum oxide. In particular, CBN's high thermal stability and chemical resistance make it suitable for sharpening in conditions where synthetic diamonds are not normally employed.

CBN offers excellent performance in sharpening knives of any steel. Due to its high resistance specs, CBN can be used dry without lubricant. This makes CBN the cleanest of the available sharpening stones.

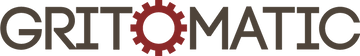

| Grit | Micron |

|---|---|

| 📈80 grit | 160μm-200μm |

| 📈150 grit | 80μm-100μm |

| 📈400 grit | 28μm-40μm |

| 📈800 grit | 14μm-20μm |

| 📈2000 grit | 5μm-7μm |

| 📈5000 grit | 2μm-3μm |

Attention! Hapstone Premium CBN stones may seem bald out-of-the-box. This is by design.

Hapstone Premium CBN can be used without lubricants.

Premium CBN stones may become darker over time due to natural metal oxidizing. It does not affect the sharpening.

Premium CBN stones do not require any preparations.

Pressure control means applying only the minimum, steady force needed for the abrasive to begin cutting. With guided systems, you are holding the stone, guide rod, and stone holder in the air, so the total mass matters. A lighter setup improves tactile feedback and makes it easier to keep pressure consistent.

Why It Matters

- Edge integrity: Excess pressure can bend the apex and move contact away from the actual cutting edge.

- Cutting efficiency: Too much force causes metal deformation instead of clean cutting, reducing sharpness and polish.

- Abrasive wear: Overload accelerates uneven wear, grain chipping, and unwanted scratches.

- Geometry control: High force makes it harder to maintain angle accuracy, especially on thin bevels or low angles.

- Heat and fatigue: More pressure creates excess friction and heat, which can harm both the edge and the user’s consistency.

Best Practices

- Start light: Increase pressure only until you feel the abrasive begin to cut, then keep it steady.

- Reduce with finer grit: The finer the stone, the lighter the touch required.

- Maintain consistency: Equal pressure on both sides removes previous scratches and ensures even refinement.

- Use smooth strokes: Controlled, deliberate movements improve feedback and angle stability.

- Keep it lightweight: Choose light stones, guide rods, and holders for better control and less hand strain.

When Pressure Is Too High

- Loss of bite: The abrasive stops cutting effectively even as force increases.

- Edge rollover: The apex deforms or folds, forcing a return to a coarser grit.

- Random scratches: Damaged abrasive grains leave isolated, deep marks.

- Uneven stone wear: The surface loses flatness faster, reducing accuracy and finish quality.

Bottom line: Let the abrasive do the work. Light, steady pressure with a lightweight setup yields sharper edges, longer stone life, and more predictable results.

![Hapstone Premium CBN Narrow Stone [6" x ½"]](http://es.gritomatic.com/cdn/shop/files/Hapstone_20Premium_20Narrow_20CBN_20lowres_490x.progressive.jpg?v=1761738784)

![Anillo de tapón asistido por primavera [6 mm]](http://es.gritomatic.com/cdn/shop/files/Hapstone_20Spring-Assisted_20Stopper_20Ring_201_600x.progressive.jpg?v=1764726732)

![Hapstone Suspensión de diamante de poli [5 ml]](http://es.gritomatic.com/cdn/shop/files/Hapstone_20Diamond_20Suspension_205_20ml_201_600x.progressive.jpg?v=1764726680)